Content

Electric stackers are essential equipment in modern warehousing and logistics environments. They are widely used for loading, unloading, transporting, and stacking goods, especially in space-constrained warehouses, workshops, or retail environments.

Core Components and Operating Principles of Electric Stackers

Electric stackers are primarily powered by electricity, and their core workflow can be summarized as follows:

Power System and Drive

Electric stackers are powered by batteries (typically lead-acid or lithium batteries). The batteries power the drive motor and hydraulic pump motor.

- Drive Motor: Controls the stacker's movement. The operator controls speed and direction using the handle or steering wheel, enabling horizontal transport.

- Hydraulic Pump Motor: This is the core of the stacking function. When the operator activates the lift control, the hydraulic pump motor drives the hydraulic pump, pressurizing hydraulic oil from the tank into the hydraulic cylinder.

Lifting System (Stacking Function)

Hydraulic oil enters the hydraulic cylinder, pushing the piston upward. The piston connects to the mast and forks.

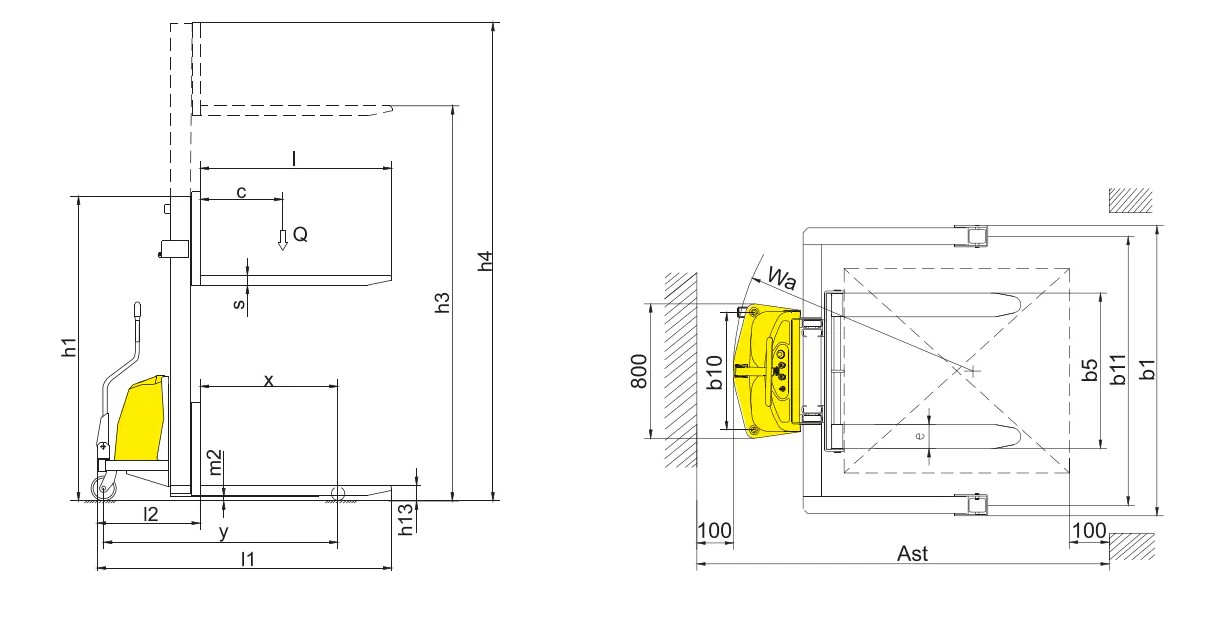

- Mast: The mast of an electric stacker is typically multi-stage (e.g., two or three). Hydraulic pressure coordinates the mast and chain to vertically raise and lower the forks, enabling stacking and retrieval of goods.

- Forks: The forks carry pallets or goods and are the components directly involved in loading and unloading.

Control and Safety Systems

Modern electric stackers are equipped with advanced controllers for precise control of travel and lifting speeds. Safety features include:

- Emergency Brake: Typically, there's a red mushroom-shaped button that instantly cuts power in an emergency.

- Reverse Brake/Contact Switch: Designed to protect the operator from being crushed, when the operator's back contacts the switch on the handle, the stacker moves a certain distance in the opposite direction.

- Limit Switch: Ensures that the forks automatically stop when they reach their highest or lowest position.

Electric Stacker Types and Applications

Electric stackers come in various types depending on application requirements, but their operating principles are fundamentally the same:

- Fully electric stackers: All functions (travel and lift) are electrically powered, making them the preferred choice for efficient handling and stacking.

- Semi-electric stackers: Lifting is electrically powered, but travel requires manual propulsion. They are suitable for smaller warehouses or infrequent loading and unloading.

- Reach stackers: The mast extends forward, providing greater stability and suitable for high-level stacking.

By combining battery power, hydraulic drive, and sophisticated controllers, electric stackers achieve efficient and stable handling and stacking of goods both vertically and horizontally, making them key equipment for improving warehouse efficiency.