Content

The core difference between electric stackers and electric forklifts lies in their design and application: electric stackers have a more compact structure and a smaller turning radius, specifically designed for vertical stacking in narrow aisle warehouses; while electric forklifts have a heavier chassis and faster travel speed, making them more suitable for medium to long-distance ground handling and high-intensity heavy-duty operations. If your warehouse space is limited and you primarily move goods between shelves, an electric stacker is a more cost-effective option.

I. Core Definitions: Precisely Distinguishing Between Two Types of Warehouse Equipment

Before purchasing, we need to clarify the differences in the design intent of electric stackers and electric forklifts:

Electric Stacker

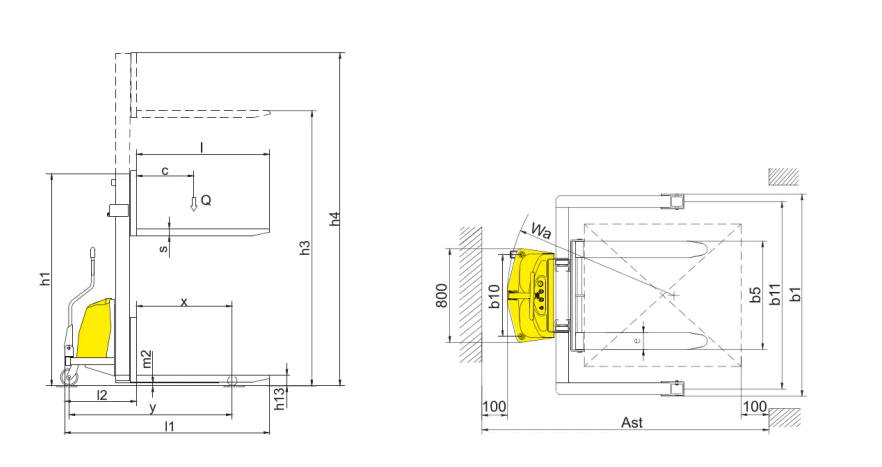

Usually refers to a walk-behind or stand-on type of light and compact lifting equipment. It relies on support legs to balance the load, and its body is extremely short, making it a space master for narrow aisle warehouses.

Electric Forklift

Usually refers to a sit-down counterbalanced forklift. It relies on a counterweight at the rear to balance the weight on the forks, is larger in size, and has powerful performance.

II. In-Depth Comparison: Four Dimensions of Differences

1. Aisle Width Requirements

The biggest advantage of electric stackers is their space utilization. Because they lack a large counterweight at the rear, they typically only require an aisle width of 2.2 meters to 2.6 meters to complete turning and stacking. In contrast, traditional electric forklifts usually require an aisle width of 3.2 meters to 3.8 meters or more. This means that using a stacker can free up twice as many shelf spaces.

2. Load Capacity and Lifting Height

Electric Forklifts: Load capacity usually starts from 2 tons, and can even reach over 10 tons. Due to their high stability, they have stronger high-position lifting capabilities.

Electric Stackers: Common load capacities are 1 ton, 1.5 tons, and 2 tons. Although the load capacity is slightly lower, for standard pallet operations in industries such as e-commerce, medical, and food, the performance of electric stackers is more than sufficient.

3. Operating Licenses and Legal Compliance

According to the latest safety regulations in 2026, most sit-down counterbalanced forklifts must be operated by personnel holding a special equipment operation certificate (forklift license). Some small, walk-behind electric stackers have relatively relaxed certification requirements in certain regions or for specific specifications, reducing labor costs for businesses.

4. Price and Acquisition Costs

Under the same load capacity conditions, the price of an electric stacker is usually only 1/2 or even 1/3 of that of a counterbalance electric forklift. For small and medium-sized enterprises or budget-sensitive projects, deploying multiple stackers for distributed operations is often more efficient than purchasing a single large forklift.

III. Why will businesses prefer "electric stackers" in 2026?

With the popularization of the "narrow aisle, high rack" warehousing model, the search volume for electric stackers continues to rise. Modern electric stackers already possess the following technological advantages:

Lithium-ion Battery Technology

Supports fast charging and can be charged and used at any time, solving the problem of troublesome maintenance of lead-acid batteries.

EPS Electronic Steering

Extremely easy to operate, even female employees can easily handle it.

Intelligent Safety System

Features functions such as high-position speed limiting and ramp self-locking, greatly reducing the rate of warehouse accidents.

Choosing the Right Equipment

Choose an electric stacker: If your warehouse has standard indoor epoxy flooring, narrow aisles, a load capacity of less than 2 tons, and you are pursuing the highest space utilization ratio.

Choose an electric forklift: If your working environment includes outdoor surfaces, requires frequent long-distance transportation, or the goods being handled are oversized and heavy equipment.