Content

An electric stacker, also known as an electric forklift, is an industrial vehicle used for handling and stacking goods. It is primarily powered by electricity, using forks mounted on a mast to lift goods from the ground to a certain height and then stack them onto shelves or other items. Compared to manual stackers, electric stackers significantly reduce operator physical labor, improving work efficiency and safety. This type of stacking equipment is an indispensable material handling device in modern warehousing and logistics.

Learning About Electric Stackers

Electric stackers come in a wide variety of types, classified by their drive, operation, and functionality. Common categories include:

- Electric walk-behind stackers: The operator walks behind the stacker and is suitable for short-distance handling in confined spaces.

- Electric stand-on stackers: The operator stands on the stacker to operate, offering faster speeds and suitable for medium-distance handling.

- Electric sit-on stackers: The operator sits inside the stacker, offering increased comfort and speed. They are typically used for long-distance handling and high-level stacking in large warehouses.

Each type of electric stacker is designed with different load capacities and lift heights to meet the needs of different warehouse operations.

Stacker Operation

Operating an electric stacker requires specialized training. Proper operating procedures typically include:

- Inspection: Check the stacker's battery, brake system, and fork condition before starting to ensure it is in good working order.

- Loading: Slowly insert the forks into the bottom of the pallet to ensure the load is balanced and stable.

- Lifting: Smoothly lift the load to the desired height, ensuring there are no obstacles.

- Moving: Maintain a moderate speed when moving, especially when turning or navigating narrow aisles.

- Unloading: Place the load in the designated location, slowly lower the forks, and fully withdraw them.

Consistently following stacker safety procedures is key to avoiding accidents.

Benefits of Using Electric Stackers in Warehouses

- Increased Efficiency: Electric propulsion makes handling and stacking loads faster, reducing operation time.

- Labor Savings: Automated or semi-automated operation reduces manual handling burden.

- Increased Safety: Specialized handling equipment reduces workplace injuries caused by improper operation or dropped objects.

- Space Optimization: Efficient stacking maximizes vertical space usage in the warehouse.

How to Choose the Right Stacker for Your Warehouse Operations

Choosing the right electric stacker requires comprehensive consideration of the following factors:

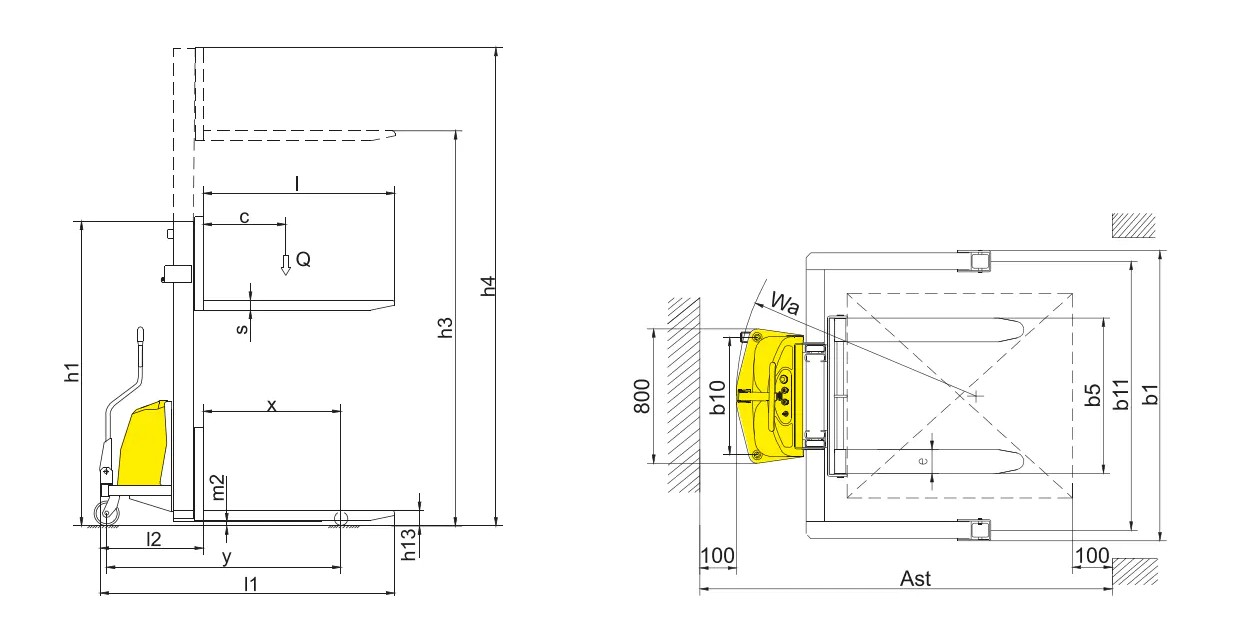

- Load Capacity: Ensure the stacker's rated load exceeds the weight of your heaviest goods.

- Maximum Lift Height: Ensure it meets your racking height requirements.

- Aisle Width: Choose a model with a small turning radius suitable for narrow aisles.

- Operating Environment: Consider indoor/outdoor use and floor conditions.

Good Maintenance for Long-Term Use

- Battery Care: Charge and discharge according to manufacturer guidelines to avoid overcharging or over-discharging.

- Mechanical Inspection: Regularly inspect forks, chains, hydraulics, and brakes.

- Cleaning: Keep the stacker clean to prevent dust and dirt from affecting performance.

Electric Stacker: A Critical Equipment for Successful Operations

In summary, electric stackers are an indispensable core piece of equipment in modern warehouse logistics. Choosing the right electric stacker model and properly maintaining it can significantly improve work efficiency and safety, while also helping businesses better manage their warehouse space. They are essential material handling equipment for efficient, safe, and successful operations.